The Bullwhip Effect in Supply Chains: What It Is and How to Keep It Under Control

Last Updated on March 25, 2025 by Tatyana Vandich

What is the Bullwhip Effect in Supply Chains? Understanding Causes and Impacts on Inventory and Efficiency

If you’re in logistics and supply chain management, you’ve probably heard of the bullwhip effect, also known as the Forrester effect. It’s a common challenge that can create huge, costly headaches for businesses. Basically, it’s when small changes in customer demand end up creating much bigger waves in the supply chain—sometimes all the way up to raw material suppliers. So, something as small as a sudden spike in demand for a product can snowball into major inefficiencies, inaccurate inventories, and even excess stock no one ends up needing.

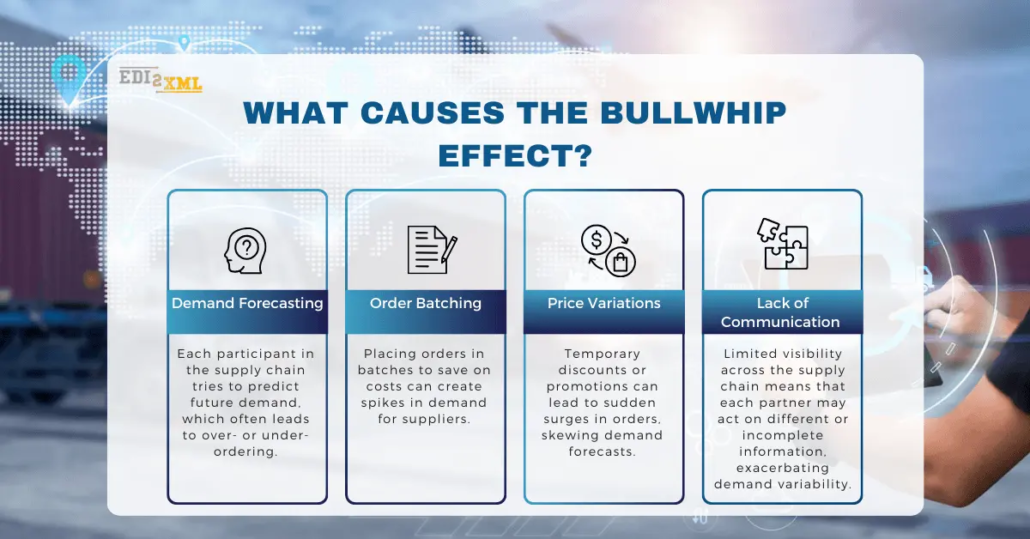

What Exactly Causes the Bullwhip Effect?

There are a few big drivers behind the bullwhip effect:

- Inaccurate Forecasting: Every player in the supply chain—from retailers to manufacturers—tries to predict demand. But forecasts are rarely perfect, so each party may over- or under-order to cover themselves.

- Order Batching: Many businesses order in bulk to cut costs. But this batch ordering can cause uneven spikes in demand, which don’t actually reflect what customers want right now.

- Price Changes and Promotions: Discounts or temporary deals can drive sudden surges in orders. Great for sales, but not so much for the supply chain—it often means that everyone upstream scrambles to keep up, which can lead to an oversupply later.

- Limited Visibility Across the Supply Chain: Without transparent, real-time data, every participant in the chain relies on their own (sometimes outdated) info. This leads to decisions that don’t always sync up with actual customer demand.

How Does the Bullwhip Effect Impact Your Business?

The bullwhip effect in the supply chain isn’t just a theoretical problem—it can have a real impact on profitability, efficiency, and customer satisfaction. When supply chains are reacting to outdated or inaccurate data, they’re prone to overstocking, understocking, and inaccurate inventories. This translates to wasted resources, higher carrying costs, and lost sales if products aren’t available when customers need them. And these inefficiencies affect nearly every part of the business, from supply chain management to the customer experience.

Where Does the Bullwhip Effect Have Its Greatest Impact?

The bullwhip effect has its greatest impact on manufacturers and suppliers at the beginning of the supply chain. As you move further from the consumer (e.g., from retailers to wholesalers to manufacturers to raw material suppliers), small changes in customer demand get magnified. This leads to:

- Overproduction or shortages,

- Excess inventory costs,

- Inefficient resource use,

- Strained relationships between supply chain partners.

Manufacturers and suppliers bear the brunt because they react to wildly inflated orders, not actual demand, causing disruptions and higher costs.

How to Prevent the Bullwhip Effect: Practical Solutions

Now, let’s talk solutions. With all the buzz around supply chain analytics and retail analytics platforms powered by AI, there’s good news: you don’t have to just put up with the bullwhip effect. Solution like Electronic Data Interchange (EDI) can help to smooth out these swings in demand and keep your supply chain running more predictably.

Expanding on Real-Time Data Accuracy with EDI Integration, let’s dive deeper into the EDI process and how specific EDI documents can help avoid or minimize the bullwhip effect in the supply chain.

Real-Time Data Accuracy with EDI Integration

EDI allows companies to seamlessly exchange business documents with their supply chain partners, so everyone is finally on the same page — whether retailers, suppliers, or manufacturers.

With EDI, real-time data flows throughout the supply chain, so everyone is working with the same numbers and the same information. This visibility is powerful because it helps everyone avoid the wild swings in ordering that often lead to the bullwhip effect.

Key EDI Documents That Help Keep the Bullwhip Effect in Check

To really understand how EDI can make a difference, let’s look at a few basic EDI documents that are crucial for keeping supply chain data accurate:

- EDI 850 (Purchase Order): This is where everything starts. When retailers place an order, they use the EDI 850 to tell suppliers exactly what they need and when they need it. This helps suppliers plan inventory and production right away, so there’s less scrambling to meet demand at the last minute.

- EDI 855 (Purchase Order Acknowledgment): After receiving the purchase order, suppliers respond with the EDI 855. This document confirms the order and lets the buyer know if there are any changes or adjustments. It’s a simple way to make sure both sides are on the same page from the start.

- EDI 856 (Advanced Shipping Notice): When an order is shipped, the supplier sends the EDI 856 to let the retailer know what’s on its way. This heads-up means the retailer can plan for incoming stock and avoid placing extra orders just because they’re unsure of inventory status.

- EDI 846 (Inventory Inquiry/Advice): This document is basically a real-time inventory update. By sharing up-to-date stock levels, both suppliers and retailers can adjust orders based on what’s actually available, helping everyone avoid over-ordering or under-ordering.

- EDI 860 (Purchase Order Change Request – Buyer Initiated): Sometimes retailers need to adjust an order after it’s been placed—maybe demand has changed, or forecasts were off. With the EDI 860, they can make those changes quickly without starting the order process over. This keeps things moving smoothly and helps both sides respond flexibly.

How EDI Helps the Supply Chain Flow Smoother

So, here’s how it all plays out in a typical situation:

- A retailer sends an EDI 850 Purchase Order to their supplier.

- The supplier replies with an EDI 855 to confirm the details.

- If stock levels change, the supplier shares an EDI 846 Inventory Update to keep everyone informed.

- When the order is on its way, the EDI 856 Advanced Shipping Notice gives the retailer a clear picture of when to expect the inventory.

- And if something shifts with demand, the retailer sends an EDI 860 Change Request, making it easy to adjust the original order.

All of this real-time data sharing cuts down on misunderstandings and delays. Everyone in the supply chain has what they need to act quickly and accurately, so there’s less overstocking, fewer surprises, and a much lower chance of reacting in ways that cause the bullwhip effect.

At EDI2XML, we make these EDI processes simple, fast, and effective, so you can keep your supply chain on track and avoid the typical headaches that come with demand fluctuations.

Benefits of Implementing EDI for Supply Chain Management

EDI Enhances Visibility and Transparency: When your supply chain has access to the same data on inventory, orders, and customer demand, there’s less room for costly surprises. Real-time transparency helps each player in the supply chain make better decisions based on accurate, up-to-date data.

Faster Reaction to Demand Changes: With EDI integration, demand changes get communicated instantly. So, if you’re running low on a popular item, suppliers get notified in real-time, allowing them to respond more efficiently. This kind of responsiveness is crucial to cutting down the exaggerated reactions that fuel the bullwhip effect.

Streamlined Communication Across the Supply Chain: Relying on manual processes—like emails or spreadsheets—to update inventory or demand data can be slow and prone to error. EDI ensures that critical data updates flow automatically between systems, improving response times and helping your business stay agile.

Seamless EDI Integration with ERP and CRM Systems

When it comes to effective supply chain management, ERP – Enterprise Resource Planning (like SAP or Microsoft Dynamics) and CRM – Customer Relationship Management (like Salesforce), play a huge role.

Integrating EDI with ERP and CRM systems is essential for a smooth supply chain. EDI links your systems to those of your partners to share real-time data across the entire chain.

At EDI2XML, we specialize in connecting EDI with ERP and CRM systems, so data moves instantly from one system to another.

Imagine you’re a retailer using Salesforce for customer orders and SAP for business operations, and EDI for communicating with suppliers. When a customer order comes in through Salesforce, it’s instantly visible in SAP, so inventory gets updated right away. Then, the EDI system can automatically send a purchase order to the supplier, ensuring there’s no delay. This real-time communication prevents issues like overstocking, missed orders, or lag in responding to demand changes.

How EDI2XML Can Help

At EDI2XML, we specialize in EDI and business system integration, with a focus on creating seamless data exchanges that improve supply chain management. Our EDI solutions like Fully Managed EDI or EDI Web Service are designed to make data sharing smooth and accurate, so your business can prevent the bullwhip effect and work with reliable data, every time.

Imagine not having to worry about inaccurate inventories or overcompensating for demand—just a more efficient, data-driven supply chain. Contact us today for a free consultation with our experts.

Leave a Reply

Want to join the discussion?Feel free to contribute!