This post was updated to reflect current trends and information.

Are you looking to streamline your supply chain and improve shipping efficiency? Look no further than EDI 856, the ultimate electronic document for advanced shipping notifications (ASN). In this comprehensive article, we will walk you through everything you need to know about EDI 856 and how it can optimize your logistics operations.

What is EDI 856 (ASN)?

The Advanced Ship Notice (ASN 856) is a critical Electronic Data Interchange EDI transaction used to inform trading partners about the details of pending shipments before the goods arrive. Also known as EDI 856, the ASN provides granular information on packing hierarchy, item quantities, carrier details, and expected delivery times, enabling better planning and accuracy in warehouse and distribution operations.

In different EDI standards, this electronic document can have different names, for example, in ANSI standard this electronic document is called ASN or “Advanced Ship Notice” or 856 transaction. In EDIFACT the same document is DESADV “Dispatch Advice”. Nevertheless, no matter how this document is called: Dispatch Advice, 856 Ship Notice, Advanced Ship Notice, Advance Shipping Notice, 856 transaction set, 856 Ship Notice/Manifest, ASN, ASN message, EDI 856, ANSI x12 856, it has the same mission and has the same business meaning.

The EDI 856 document is essential for streamlining the supply chain process because it provides real-time visibility and transparency throughout the entire logistics journey. An 856 Ship Notice message is intended to simplify and speed up the process of receiving goods, detailed information about the cargo, transfer of information about the shipment, and tracking the delivery. This information is used for receiving and inventory control purposes.

By sharing this information electronically, suppliers and retailers can plan and track shipments more efficiently, reducing the risk of delays, errors, and unnecessary costs.

EDI 856 – Definition and Purpose

Definition: The ASN 856 is an EDI X12 transaction set that transmits shipment details after goods have been shipped but before delivery. It is mandated by many large retailers (e.g., Walmart, Costco) to guarantee visibility and compliance.

Purpose:

-

Notify the receiver of item-level details (UPC, SKU, quantity).

-

Facilitate warehouse pre‑staging by providing pallet and carton hierarchies.

-

Integrate with ASN processing in SAP or other ERP systems to trigger inbound routing and scheduling

856 Ship Notice/Manifest does not physically accompany a shipment but is used to inform the recipient in advance, about the contents of the shipment.

Who Uses The Advanced Shipping Notice (ASN)?

The EDI 856 Advanced Shipping Notice is widely used in the supply chain by retailers, manufacturers, wholesalers, third-party logistics providers (3PLs), and even in Drop-ship fulfillment and e-commerce. It is a key document for tracking and managing shipments, providing detailed information about the contents and expected delivery of goods.

EDI 856 is especially important in traditional retail replenishment and drop-ship fulfillment scenarios, where it helps streamline inventory management and order processing.

By delivering advance shipment details, the ASN helps businesses optimize their operations, improve warehouse management, and reduce delays in receiving goods.

For more information about Drop-Ship, you can read our blog: 4 Challenges of EDI and Drop-Ship in eCommerce

Basically, the sender of Advanced Ship Notice is the warehouse, raw materials supplier, and carriers who are responsible for specifying and communicating the contents of a shipment.

The 856 Ship Notice/Manifest may be the most complicated document to implement because different trading partners can customize their requirements for EDI 856. In addition, ASN has a multitudes level of information and a great volume of data.

A key feature of the Ship Notice/Manifest is the hierarchical level of data. The supplier can describe the details of a shipment due to a multitude of levels of data. Each level in the Ship Notice/Manifest describes the related details about a physical shipment. Usually, in the retail industry there are six defined levels in an EDI 856 (ASN):

- Shipment – Information about shipment moving from a supplier (origin place) to a receiving location (Client), such as a bill of lading number, ship to, ship from, etc. There is only one shipment level in each transaction set.

- Unit load – Information about a physical shipping item marked with a Serial Shipping Container Code and, consists of transport packages marked for multiple final destinations.

- Order – Information related to the client’s original Purchase Order (EDI 850) such as purchase order number, buying place, division number, etc.

- Tare – Information about the pallets. This level may be skipped if there are no identifiable pallets.

- Pack – Information about the shipping package (cartons, racks, bags, etc.,) such as carton serial number. If there are no identifiable packs, this level may be skipped.

- Item – Information about the shipped goods, such as SKU identification, quantity shipped, etc.

Book a FREE one-on-one EDI consultation session with our in-house experts

EDI 856: Understanding the Components of a Document

An EDI 856 document, also known as the Advanced Shipping Notice (ASN), is a detailed electronic record that conveys essential information about a shipment. Key components typically include:

- Header Information: This section provides general shipment details, including the purchase order number, ship-to address, and expected delivery date. It sets the context for the entire shipment.

- Line Item Details: This section includes specific information about each item being shipped, such as the product code, description, quantity, and unit of measure. It helps recipients identify and verify the contents of the shipment.

- Packaging Information: Here, you’ll find details about the shipment’s packaging, including the number of pallets, cases, or individual units. This information is crucial for efficient handling and storage.

- Carrier and Tracking Information: This part provides details about the carrier responsible for the shipment, including tracking numbers and shipping labels. It allows for tracking and monitoring the shipment’s progress.

- Additional Details: Depending on industry requirements or business needs, the EDI 856 document may include additional information such as special handling instructions, lot numbers, or expiration dates. This ensures that all relevant details are communicated.

Understanding these components is crucial for businesses to ensure accurate and efficient data exchange with supply chain partners. Familiarity with the various fields helps streamline shipping processes, reduce errors, and enhance overall supply chain visibility.

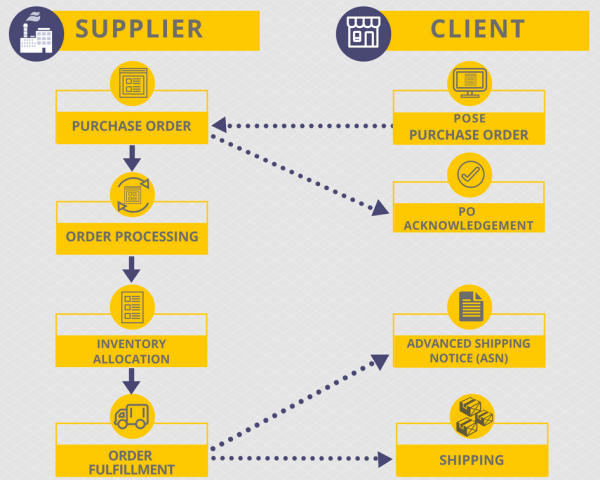

Ship Notice/Manifest Business Flow

Below we give you a simple example of Business processes that cause the Ship Notice/Manifest.

- The order process begins with an EDI 850 Purchase Order from the client.

- To confirm the receipt of a purchase order, the supplier generates a Purchase Order Acknowledgement (EDI 855). Then, the supplier has to start the order processing procedure.

- When the order is ready for delivery, the supplier collects all pertinent data relative to the shipment. Using this information, the supplier creates a Ship Notice/Manifest. The supplier must generate the Ship Notice, and transmit it to the client immediately upon closing the truck.

- The client needs to receive and integrate the data of ASN 856 into his business systems prior to the physical arrival of the merchandise.

Integration with SAP and E-Commerce Platforms

ASN in SAP: SAP uses IDocs (Inbound Delivery IDoc – DESADV) to ingest ASN 856 data. The mapping from EDI segments (e.g., BSN, HL, LIN) to SAP fields enables automatic inbound delivery creation and advanced shipping notifications.

E-Commerce Integration: Platforms like Shopify or Amazon Vendor Central leverage ASNs for order fulfillment automation. Implementing EDI ASN 856 mapping ensures inventory accuracy and faster customer notifications.

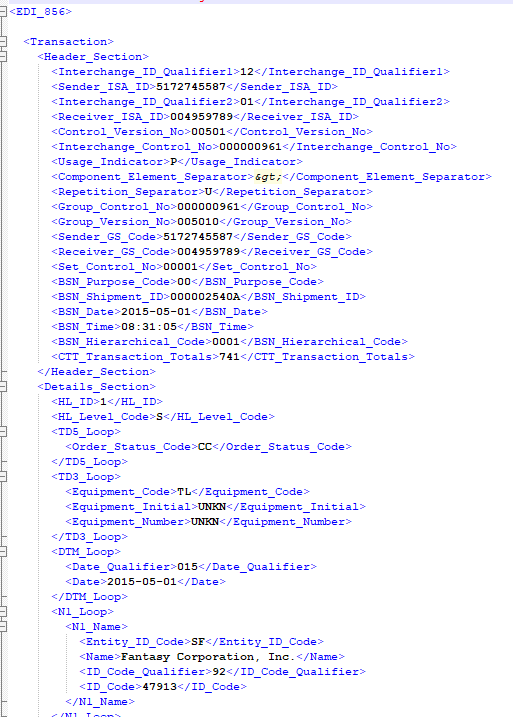

Advanced Shipping Notice (ASN) Example

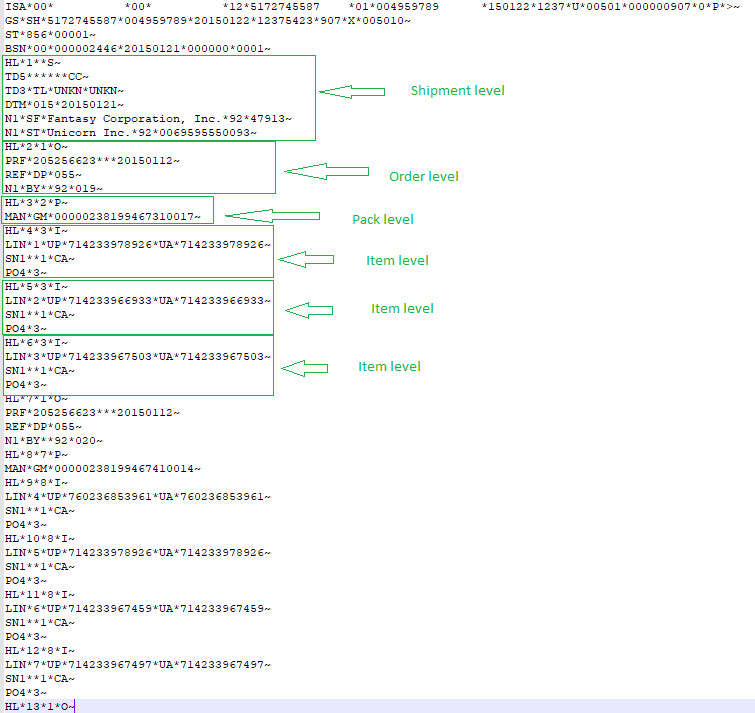

These two examples of Advanced Shipping Notice (ASN) 856 below show the XML file and the same file that was converted to EDI.

These two examples below describe how an Advanced Shipping Notice (ASN) 856 transaction set looks like in xml format, and then displays the same information in X12 format after it has been converted to EDI by our EDI2XML translation and communication service.

EDI 856 ASN (xml) Example:

EDI 856 X12 Example File:

The shipment level in the 856 EDI document refers to the level of detail provided about the shipment. This can include information such as the number of cartons or pallets in the shipment, the item numbers and quantities of the products being shipped, and other details about the shipment. The shipment level in the 856 EDI document may also include information about the carrier and transportation details associated with the shipment.

The order level in the 856 EDI document refers to the level of detail provided about the order that the shipment is fulfilling. This can include information such as the purchase order number, the customer’s order number, the date the order was placed, and other details about the order. The order level in the 856 EDI document may also include information about the items being shipped, including item numbers, quantities, and unit of measure. It also may include information about the shipping and delivery details, such as the requested delivery date, shipping address and shipping instructions.

The pack level in the 856 EDI document refers to the level of detail provided about the packaging of the items within the shipment. This can include information such as the number of items within each package, the type of packaging used, and the weight and dimensions of each package. The pack level in the 856 EDI document may also include information about the labeling of each package and any special instructions related to the packaging of the items. This level of information is important for the logistics and warehouse operations of the recipient of the shipment.

The item level in the 856 EDI document refers to the level of detail provided about the individual items within the shipment. This can include information such as the item number, the item description, the quantity being shipped, and the unit of measure. The item level in the 856 EDI document may also include information such as the item’s weight, dimensions, and packaging information. This level of information is critical for the logistics and warehouse operations of the recipient of the shipment. It also allows the recipient to match the received items with the purchase order and track inventory levels. This level of detail is important for the recipient to be able to process and receive the shipment accurately and efficiently.

What Are the Benefits of Implementing the Ship Notice/Manifest for the Supply Chain?

Implementing EDI 856 in your supply chain can unlock a wide range of benefits that can significantly improve your business operations and overall competitiveness. Some of the key advantages of adopting EDI 856 include:

- Improved Inventory Management: With the detailed information provided in an EDI 856 document, businesses can better plan and manage their inventory levels, reducing the risk of stockouts or excess inventory.

- Enhanced Shipping Efficiency: By automating the shipping process and eliminating manual data entry, EDI 856 can help businesses streamline their logistics operations, leading to faster delivery times and reduced shipping costs. Reduce off-loading time at receiving dock. Acceleration of goods acceptance, due to previously received information on the composition and structure (as packed) of the supply.

- Increased Accuracy and Reliability: EDI 856 documents are transmitted electronically, which minimizes the risk of errors and inaccuracies that can occur with manual processes. This improved data accuracy helps to build trust and strengthen relationships with supply chain partners.

- Better Visibility and Collaboration: The real-time information provided by EDI 856 documents allows businesses to track shipments more effectively and collaborate more closely with their suppliers and customers, enhancing overall supply chain visibility. The EDI 856 (ASN) connects with bar code labels on transported pallets, boxes, or cartons, so there is the possibility of using the RFID scanner and transport package sequence number (SSCC) when accepting goods.

- Cost Savings: By automating the shipping process and reducing the need for manual intervention, EDI 856 can help businesses save on labor costs, paper expenses, and other administrative overhead associated with traditional shipping methods.

- Improved Customer Satisfaction: With faster delivery times, better inventory management, and more reliable shipping information, businesses can improve their customer service and satisfaction levels, ultimately leading to increased loyalty and repeat business.

Implementing EDI 856 in your supply chain can be a transformative step, enabling your business to streamline operations, enhance collaboration, and gain a competitive edge in the market. By embracing this powerful EDI document, you can unlock new opportunities for growth and success in your supply chain management efforts.

6. Frequently Asked Questions (FAQ)

Q1: What does ASN 856 stand for?

A: ASN stands for Advanced Shipping Notice; the transaction set ID is 856 in X12 standards. (edi 856 definition)

Q2: Who issues the Advanced Shipping Notice?

A: The supplier or shipper generates and sends the ASN to the buyer once goods are dispatched. (advanced shipping notice is issued by)

Q3: How is ASN 856 used in SAP?

A: SAP ERP consumes the ASN via DESADV IDocs, automatically updating Inbound Delivery and warehouse processes. (asn meaning in sap)

Q4: What is the difference between ASN 856 and EDI 945?

A: ASN (856) notifies about shipment details; EDI 945 confirms shipment receipt at the warehouse.

Advantages of Implementation of Advanced Ship Notice

The implementation of EDI 856, or the Advanced Shipping Notice, can significantly improve visibility and collaboration throughout the supply chain. By providing detailed, real-time information about shipments, this powerful EDI document enables better coordination and cooperation among all supply chain stakeholders.

- Eliminates the need for paper-based communications

- Optimization of the process of goods acceptance.

- No data entry errors.

- Reduce administrative costs by increasing the accuracy of forecasting orders.

Integrating EDI 856 with Other EDI Documents for Seamless Operations

To maximize the benefits of EDI 856 in your supply chain, it’s essential to integrate this Advanced Shipping Notice (ASN) with other key EDI documents. By enabling a seamless flow of data, businesses can increase operational efficiency, minimize manual intervention, and make more informed decisions.

EDI 810 (Invoice)

Integrating the EDI 856 with the EDI 810 Invoice allows for a more streamlined invoicing process. By automatically matching the shipment details in the EDI 856 with the corresponding invoice, companies can reduce discrepancies, accelerate payment processing, and improve financial management. This integration ensures that the details of what was shipped align with what is being billed.

EDI 940 (Warehouse Shipping Order)

Linking the EDI 856 with the EDI 940 Warehouse Shipping Order improves warehouse operations and inventory control. The EDI 856 provides the warehouse with specific details about the contents, quantities, and packaging of the shipment. This enables warehouses to better plan for receiving, allocate space, and expedite the fulfillment process.

EDI 945 (Warehouse Shipping Advice)

Integrating the EDI 856 with the EDI 945 Warehouse Shipping Advice improves coordination between suppliers, warehouses, and customers. The EDI 945 confirms the shipment details sent in the EDI 856, helping the receiving party prepare for incoming goods, facilitating smoother receiving processes, and reducing misunderstandings or delays.

EDI 997 (Functional Acknowledgment)

By linking EDI 856 with the EDI 997 Functional Acknowledgment, businesses can track and confirm the successful transmission of their ASNs. The EDI 997 serves as a receipt confirmation, ensuring that the EDI 856 has been successfully received by trading partners. This validation helps businesses monitor and improve the reliability of their EDI processes.

EDI 753 (Request for Routing Instructions)

Although EDI 753 (Request for Routing Instructions) is less commonly mentioned in ASN integration, it can be valuable in ensuring accurate shipping details. This document is used to request specific routing instructions from the buyer or consignee, often in transportation and logistics planning. When integrated with EDI 856, it can help ensure that the shipment follows the correct delivery path, aligning transportation and delivery instructions.

By integrating EDI 856 with these key EDI documents, businesses can create a more cohesive and efficient supply chain. This integration reduces errors, increases visibility into shipments, and strengthens collaboration with trading partners. A holistic approach to EDI integration is vital for staying competitive in today’s dynamic business environment.

Choosing the Right EDI Provider for Your Organization’s Needs

Selecting the right EDI provider is a crucial step in successfully implementing and leveraging EDI 856 in your supply chain. The right partner can make all the difference in ensuring a smooth transition, reliable data exchange, and ongoing support for your organization’s evolving needs.

When choosing an EDI provider, consider the following key factors:

1. Expertise and Experience:

Look for an EDI provider with a proven track record of successfully implementing and supporting EDI 856 and other supply chain-related EDI documents. Their industry knowledge and understanding of best practices can be invaluable in navigating the complexities of EDI integration.

2. Scalability and Flexibility:

As your business grows and your supply chain needs evolve, your EDI provider should be able to scale their services and adapt to your changing requirements. Ensure that the provider can accommodate increased transaction volumes, new trading partner integrations, and any industry-specific compliance needs.

3. Integration Capabilities:

Assess the provider’s ability to seamlessly integrate EDI 856 with your existing enterprise systems, such as your ERP, warehouse management, or logistics software. A smooth integration process can significantly streamline your supply chain operations and reduce the risk of manual errors.

4. Customer Support and Responsiveness:

Reliable and responsive customer support is essential when implementing and maintaining an EDI solution. Look for a provider that offers comprehensive training, ongoing technical assistance.

How to Get Started with Ship Notice/Manifest Transaction Set (856)?

Simplify your business processes with the implementation of EDI. We offer up-to-date integrated solutions at an affordable price to enterprises of all sizes. Whether you are a supplier or retailer contact us for cost-effective EDI Implementation.