The efficient management of logistics processes involving multiple business partners is one of the main challenges faced by companies in the supply chain vertical.

There are many systems involved in the supply chain such as warehouse management systems (WMS), transportation management systems (TMS), enterprise resource planning (ERP), and much more.

However, the use of multiples of business systems and applications does not yet guarantee success.

The most important thing in the supply chain is the flow of information between the different systems, in a timely and efficient manner; this is called “data integration” which is necessary so different heterogenous systems can “communicate” with each other in a close to “real-time” fashion.

What is Supply Chain Management (SCM)?

Wikipedia gives the most accurate definition: “In commerce, supply chain management (SCM), the management of the flow of goods and services, money and information, involves the movement and storage of raw materials, of work-in-process inventory, and of finished goods as well as end to end order fulfilment from point of origin to point of consumption”.

In other words, the supply chain is the delivery of a product to a consumer. Which includes all stages from the transformation of raw materials into a finished product to delivery to the final consumer.

The main goal of the supply chain management is to coordinate all stages of the process to minimize overall costs and obtain the greatest efficiency.

What is “Integration” in the Supply Chain?

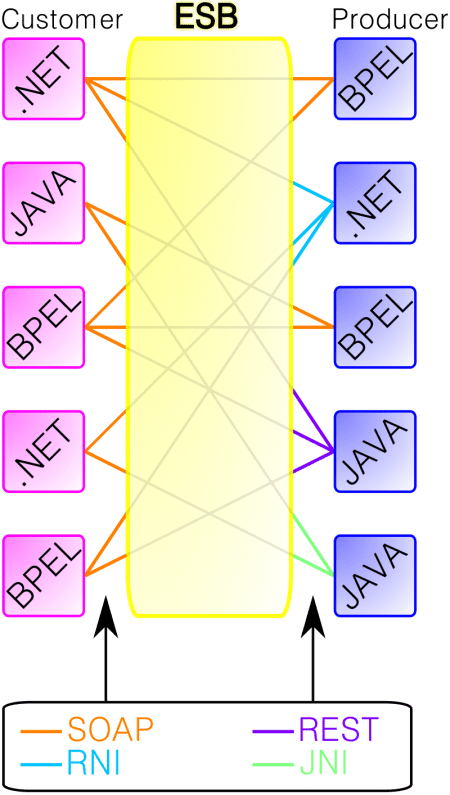

In information technology, integration is the connection of data, systems, applications, or devices to improve efficiency, productivity, and flexibility.

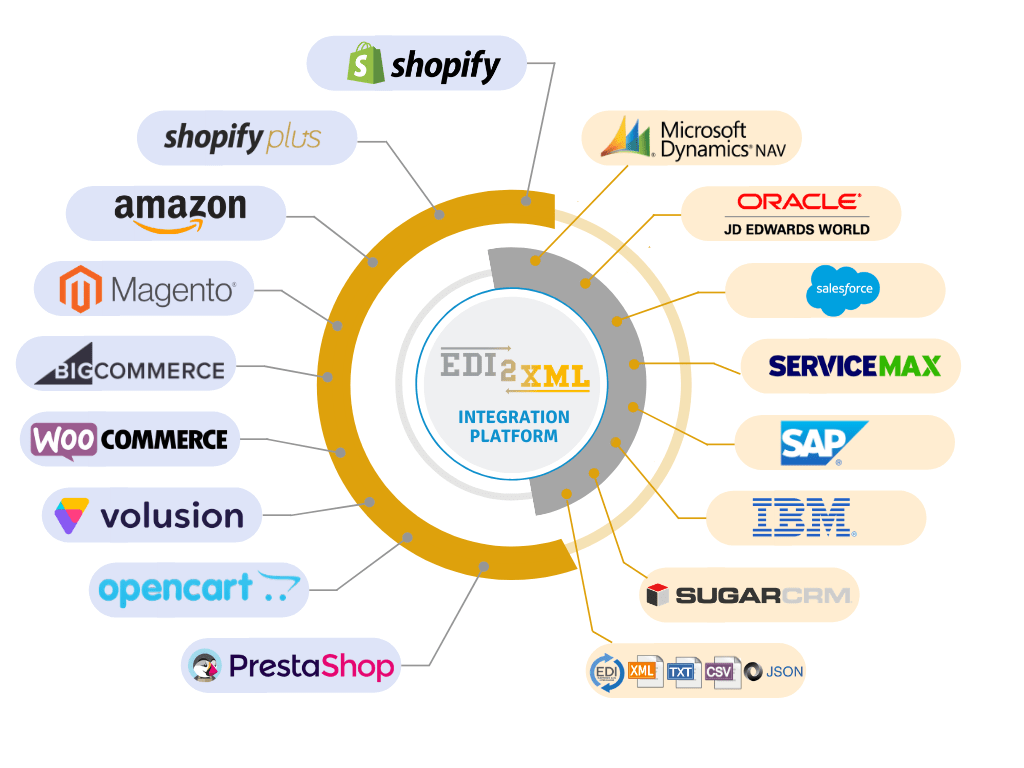

The purpose of integration in supply chain management is to combine different business systems responsible for different functions (warehouse, resource planning, accounting, electronic data interchange, etc.) that belong to different business partners to create a single efficient logistics system.

Internal and External Supply Chain Integration

There are two concepts in supply chain integration. Internal and external integration.

Internal integration is the interconnection of various business systems within one company.

External integration is the interaction between business partners through the interconnection of their numerous business systems responsible for various functions in logistics.

Typical examples of companies involved in the supply chain that require integration:

- suppliers of raw materials and supplies

- manufacturers of finished products

- warehouses, 3 pl warehouses

- transport companies and carriers

- buyers (retailers, various companies, and organizations)

- various intermediaries

Platform for full data integration across the entire supply chain

To improve efficiency, all companies involved in the supply chain need to simultaneously exchange data from different business systems. In other words, as previously mentioned, they need external integration.

Why is external integration so important? Integration in the supply chain is important because usually, any transaction goes through multiple systems such as ERP, CRM, financial, or warehouse systems. Normally, data for the same transaction must be transferred to the business partner (customer, supplier, 3pl warehouse, etc.). After receiving the data, the business partner must enter it into their business systems.

If companies have no integrated systems, data is transferred and processed manually or by downloading spreadsheets or files. Those processes are not efficient, they require a lot of resources and time, and there is a high risk of errors and data loss.

With the integration platform, companies can quickly and easily automate the exchange of information.

Useful reading: How to Choose the Right Integration Platform?

Integration platform for automating data entry

The goal of systems integration is to reduce costs and efforts for all participants in the supply chain process.

Manually entering duplicate information into several business systems takes a lot of time. Sometimes it requires hiring additional employees just to perform some of these mechanical functions. Furthermore, multiple manual entries into various systems are prone to human errors and less quality of information.

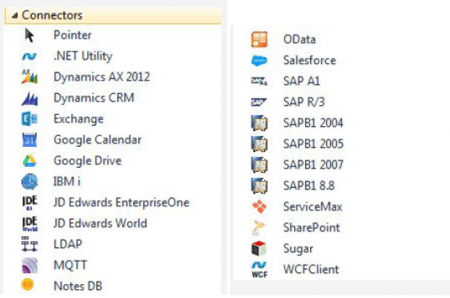

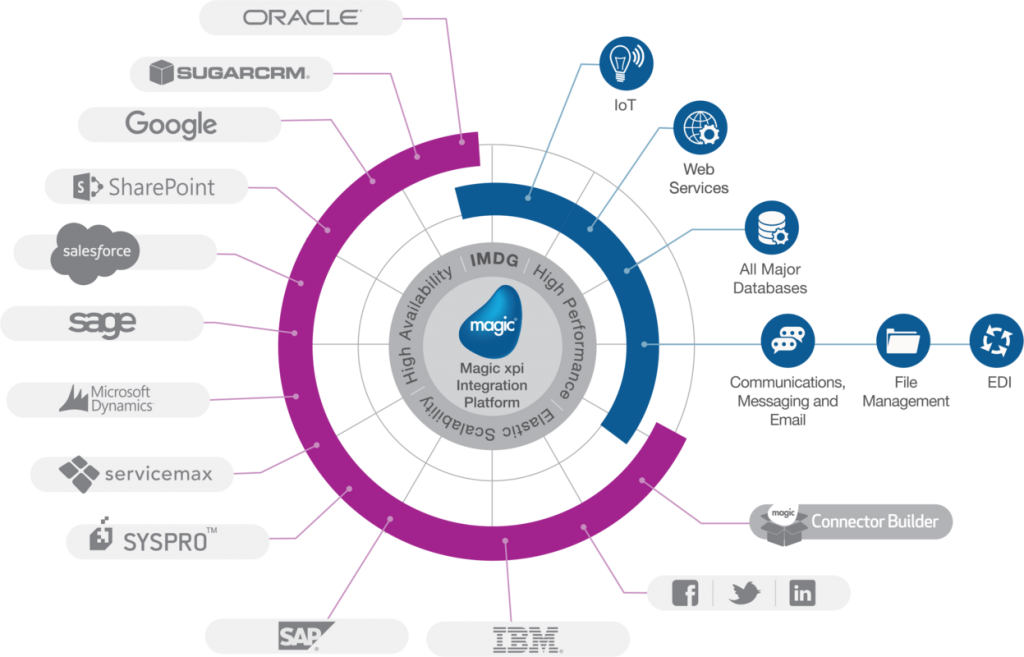

With the help of an integration platform like Magic xpi, you can quickly automate the data entry process, by reducing the time for entering data and ensuring their accuracy.

Besides, the use of modern gadgets, such as tablets and smartphones, allows data entry directly in the field (for example, when receiving goods at a warehouse), which speeds up information flows and improves customer service.

Magic xpi integration platform for efficient supply chain demand forecasting

Demand forecasting is the process of estimating future consumer demand over a given period using historical sales data and other information.

It is no secret that demand forecasting is very important for effective Supply Chain Management. Demand forecasting affects important business operations such as financial planning, raw material planning, production planning, marketing, and sales plans, as well as risk assessment.

Download Magic xpi product overview

Magic xpi can help you achieve more accurate forecasts by ensuring perfect coordination between your enterprise resource planning (ERP) and Customer relationship management (CRM) systems.

This will lead to increased profits and higher competitive advantage.

Magic xpi integration platform to improve transportation process

ERP integration with EDI, warehouse management system, and yard management software will help to improve transportation processes.

The integration of these business systems provides instant information exchange and can significantly reduce downtime.

Thus, you or your transport companies will have more time to deliver the goods.

The best integration solution for Supply chain management

Supply chain management is a broad topic in which the integration of business systems plays a key role. Data integration can help manage all the necessary processes to ensure a smooth flow at all stages of the supply chain. It can significantly improve all the processes in the supply chain, ensure fast order fulfillment, reduce cost, and improve customer service.

Being a business partner with Magic Software Enterprises for over 20 years now, we provide powerful integration solutions. We have been helping our clients make their business profitable by integrating systems.

Contact us for a free consultation.