EDI Integration with EDI2XML – Introduction

Opengear, a leader in secure and resilient network solutions, sought to streamline their business operations by automating the exchange of critical business documents with trading partners. This case study highlights how EDI2XML’s Fully Managed EDI Service provided Opengear with a scalable and efficient solution, enabling them to transition from manual processes to a fully automated EDI integration with their Salesforce CRM system. By leveraging cutting-edge technology and expert implementation, Opengear significantly improved their operational efficiency, accuracy, and customer satisfaction.

Our Client: Opengear Overview

Opengear specializes in providing secure, resilient network access and automation solutions, helping IT and network operations teams improve efficiency and reliability. Headquartered in Edison, New Jersey, with engineering in Brisbane, Australia, and production in Sandy, Utah, Opengear supports critical infrastructure across industries.

Their offerings include out-of-band management and NetOps solutions tailored to business continuity. The company has built a strong reputation for its ability to provide reliable solutions that ensure uninterrupted access to critical systems, even during network outages.

Opengear’s mission is to empower IT teams with the tools necessary to manage, monitor, and remediate network issues efficiently. With a growing customer base and expanding operations, the need for streamlined and automated processes became essential to maintaining their high standards of service.

Challenges

Before adopting EDI, Opengear faced several operational inefficiencies and challenges:

- Manual Data Entry: Employees manually processed sales orders from PDF documents into Salesforce CRM, leading to time inefficiencies and a high risk of human error. This process required significant staff hours, particularly during high-volume periods.

- Inconsistent Data Accuracy: Errors during manual entry affected order details, inventory management, and customer satisfaction. These inaccuracies often resulted in delays and the need for manual corrections, further slowing operations.

- Operational Inefficiency: Manual processes slowed order processing and fulfillment, particularly during peak periods like quarter-end and month-end. This created bottlenecks that impacted both internal operations and customer experiences.

- Delayed Processing: Manual workflows created time lags between receiving and entering orders, delaying production planning and fulfillment. The lack of real-time data visibility hindered decision-making and responsiveness.

- Limited Scalability: The growing volume of transactions outpaced the capabilities of manual processes, hindering growth. Opengear found it increasingly challenging to meet the demands of their expanding customer base without risking service quality.

- Lack of Real-Time Updates: Without automated updates, responding to changes or issues with orders was challenging. This lack of agility occasionally led to missed opportunities and strained relationships with trading partners.

These issues underscored the need for a robust, automated EDI solution to enhance efficiency, accuracy, and scalability.

EDI2XML Solution

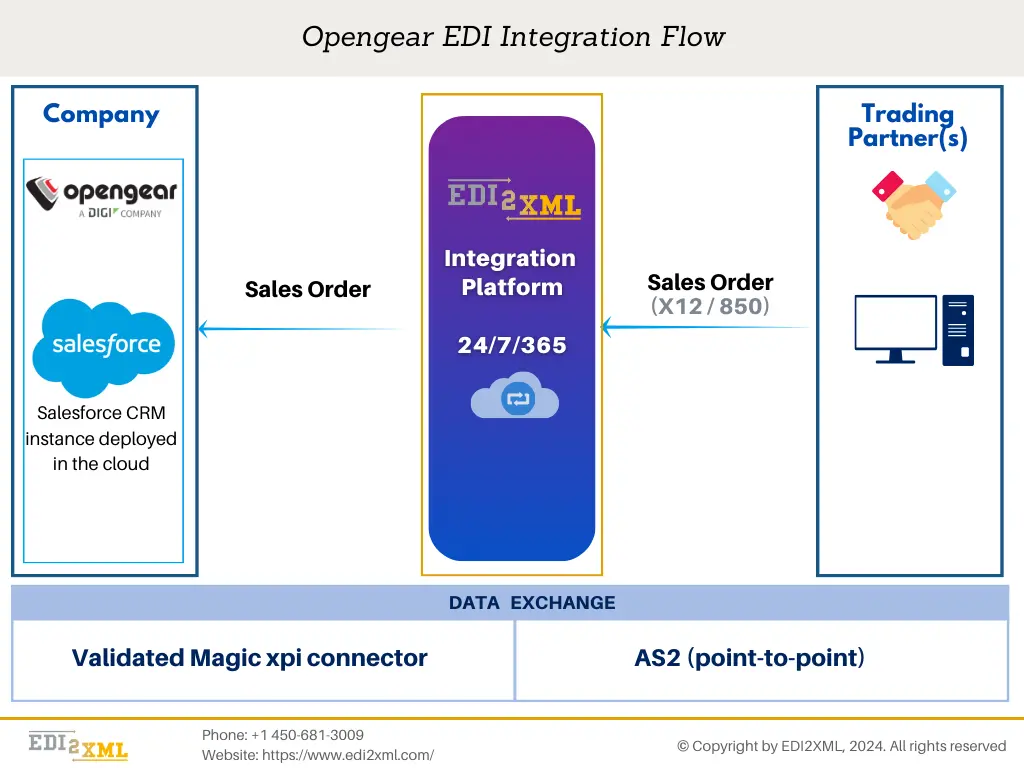

EDI2XML’s Fully Managed EDI Service was the chosen solution to address Opengear’s challenges. The integration platform seamlessly connected Opengear’s trading partners with their Salesforce CRM, automating the entire document exchange process. By leveraging EDI2XML’s expertise, Opengear was able to implement a tailored solution designed to meet their specific needs.

Key components of the solution included:

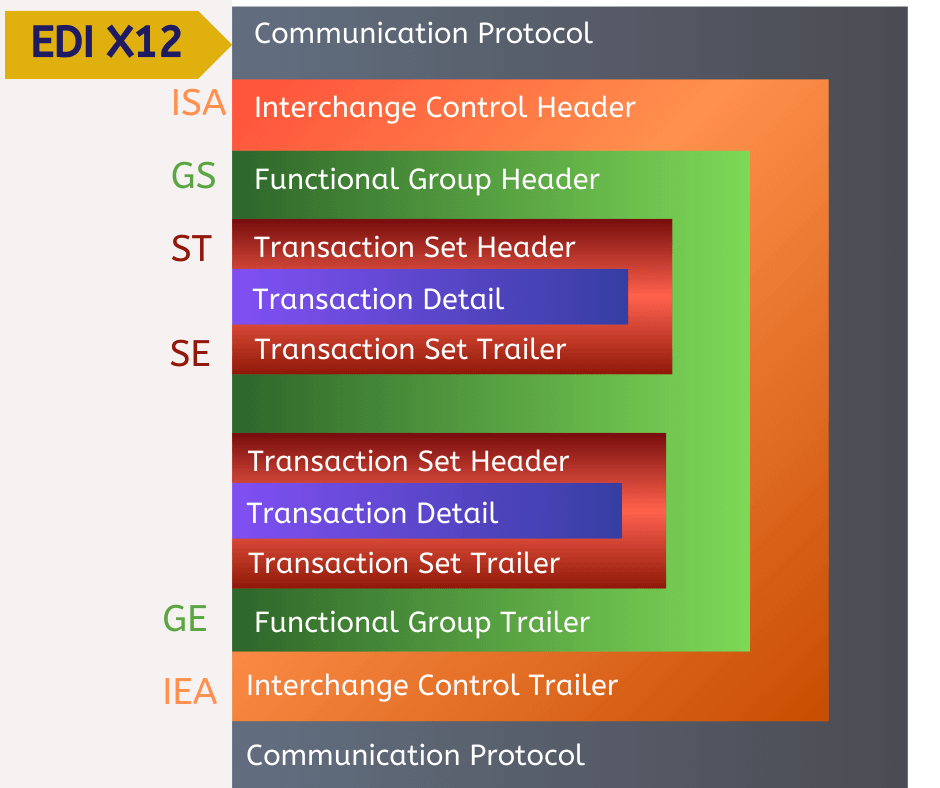

- Automated Document Collection: EDI2XML collected incoming EDI documents (e.g., X12 850 purchase orders) every 15 minutes, ensuring timely processing.

- Data Transformation: The EDI documents were transformed into formats compatible with Salesforce CRM, using validated Magic xpi connectors to ensure seamless integration.

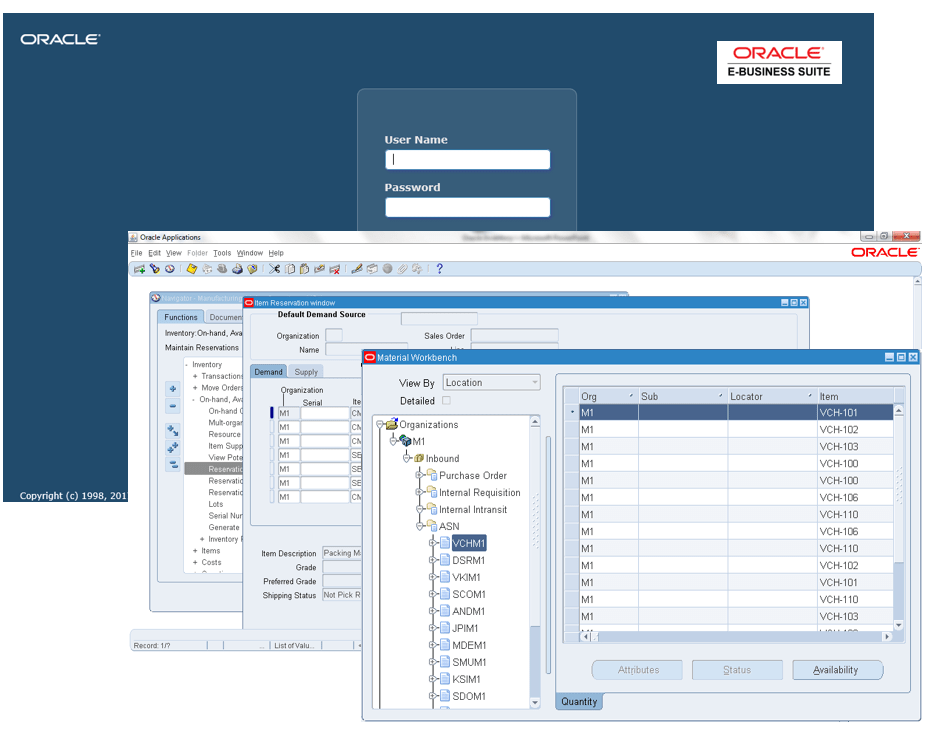

- Salesforce Integration: The transformed data was automatically transferred to Opengear’s Salesforce instance, updating relevant fields and enabling real-time visibility.

- Validation and Notifications: The platform validated item-level pricing against predefined criteria, triggering automated email notifications based on validation results. If discrepancies were found, orders were flagged, and corrective actions were initiated.

- Continuous Monitoring: Functional acknowledgments were sent to trading partners as needed, ensuring compliance and smooth operations. EDI2XML monitored all transactions to identify and resolve potential issues proactively.

Useful reading: How to get more out of Salesforce with EDI Integration

Implementation Process

The implementation was completed in several key stages:

- Initial Analysis: EDI2XML conducted a detailed analysis of Opengear’s requirements, including a review of their existing processes, Salesforce CRM configuration, and trading partner specifications. This phase involved close collaboration to ensure all requirements were accurately captured.

- Configuration: The platform was configured to handle X12 850 Purchase Orders and other relevant document types. EDI2XML set up the AS2 communication protocol for secure data exchange with trading partners.

- Mapping and Development: Business flows were developed, and data mapping was conducted to align EDI document fields with Salesforce CRM columns. This ensured accurate data transfer and compatibility.

- Testing: Comprehensive testing included full-cycle validation of data flows, functional acknowledgment processes, and Salesforce CRM integration. Opengear’s team worked closely with EDI2XML to verify all aspects of the implementation.

- Deployment: The solution went live within a month, showcasing rapid implementation capabilities. Opengear experienced minimal disruption during the transition.

- Ongoing Support: Continuous monitoring and support ensured optimal performance and timely resolution of issues. EDI2XML provided training and documentation to Opengear’s team, enabling them to maximize the benefits of the solution.

Integration with Magic xpi: Streamlining EDI and Salesforce CRM Workflows

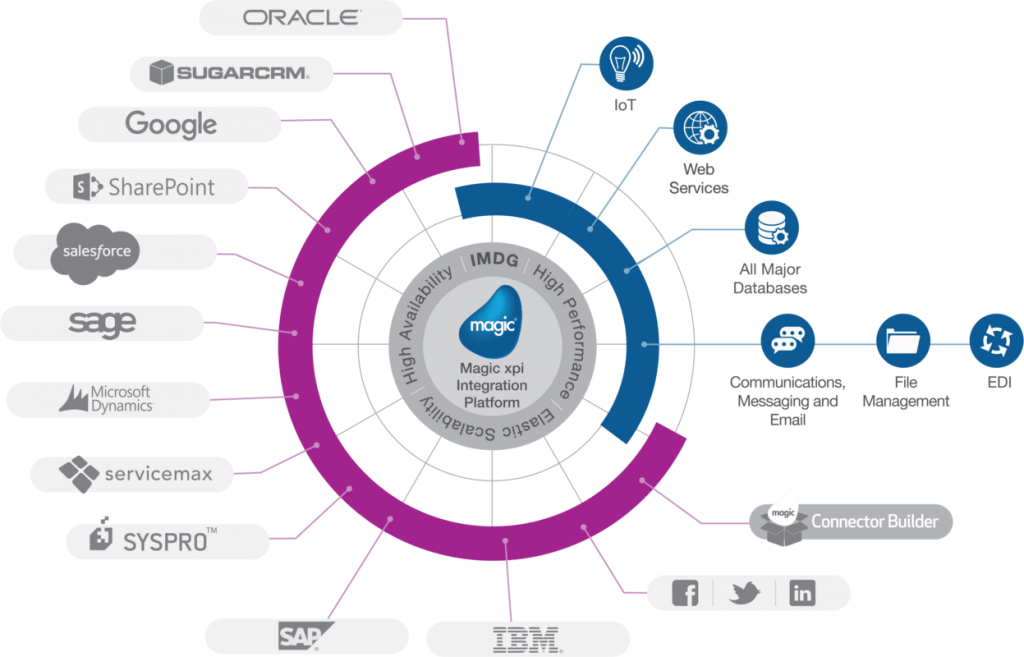

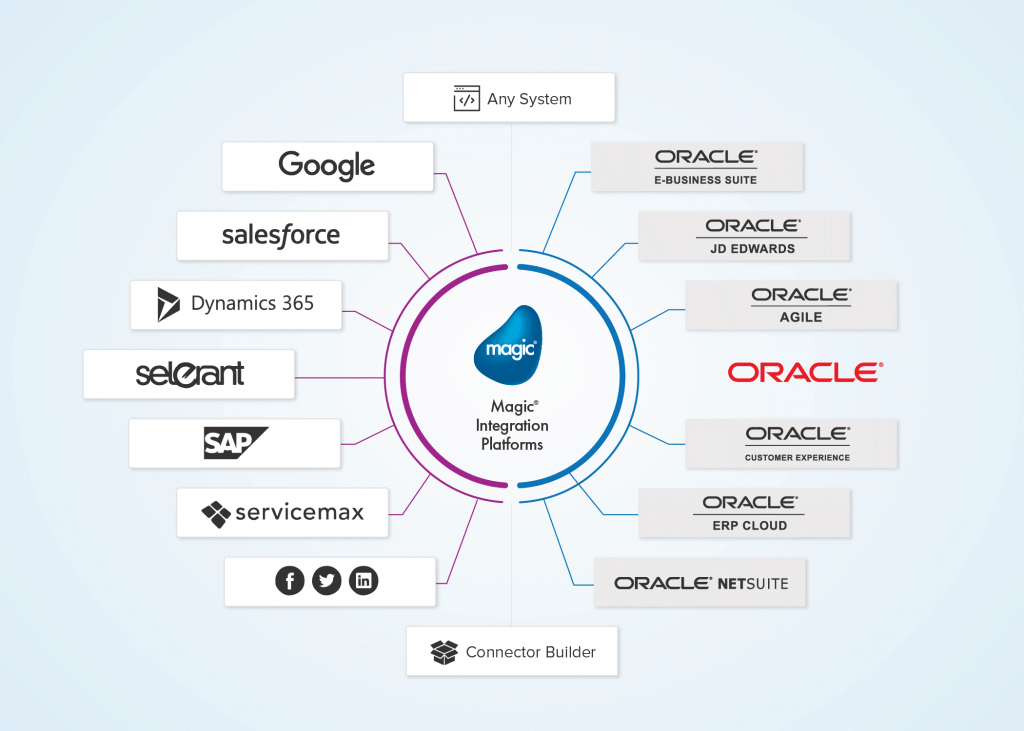

Magic xpi is a robust integration platform designed to simplify and accelerate the process of connecting diverse systems, applications, and data sources. In the context of Opengear’s integration with Salesforce CRM, Magic xpi played a pivotal role by providing a secure, scalable, and highly efficient environment for managing EDI-to-Salesforce transformations.

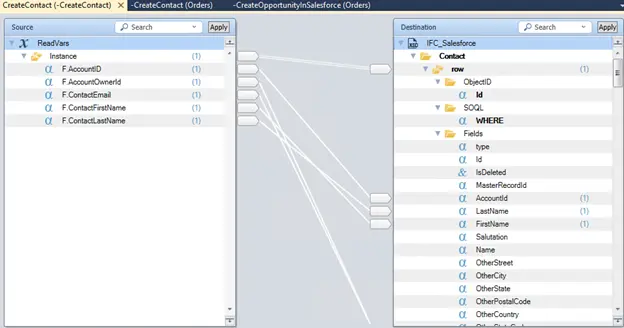

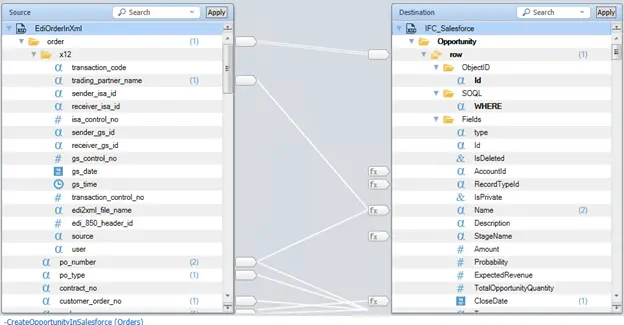

Magic xpi ensured the accurate mapping and transformation of data fields, facilitating automated and error-free document exchanges. The following points detail how Magic xpi was utilized in this implementation:

- Mapping Data Fields: Magic xpi’s graphical interface was used to map EDI document fields, such as purchase order details (X12 850) and customer information, to the corresponding fields in Salesforce CRM. For instance, product codes, quantities, and prices from incoming orders were mapped directly to Salesforce Opportunity Line Items, ensuring consistency and accuracy.

- Connector Capabilities: The Magic xpi Salesforce connector allowed for real-time data updates and retrieval. For example, customer contact details from EDI files were used to create or update Salesforce Contact and Account records automatically. This reduced manual input and enhanced data synchronization.

- Custom Business Logic: Magic xpi provided tools to define and execute custom business rules. For example, if an EDI order contained invalid product codes or incomplete shipping details, the integration logic flagged these orders for review while sending notifications to the appropriate teams.

- Visualization of Data Flows: Using Magic xpi’s mapping tools, Opengear’s team could visually understand how data moved from EDI sources to Salesforce destinations. This transparency was crucial for validating data flows during the testing phase.

- Error Handling and Notifications: In cases where mapping errors occurred, Magic xpi triggered automated notifications, allowing Opengear’s team to address issues promptly. Logs and error reports generated by Magic xpi facilitated rapid troubleshooting.

- Scalability: Magic xpi’s scalable architecture ensured that the integration could handle increasing volumes of EDI transactions as Opengear’s operations expanded. Adding new trading partners or document types required minimal adjustments to existing mappings.

The integration process, powered by Magic xpi, was instrumental in transforming Opengear’s manual workflows into efficient, automated processes, saving time and reducing errors. Below are examples of data mappings between EDI documents and Salesforce CRM, as shown in Magic xpi’s interface:

- Mapping Opportunity Line Items: EDI order details, such as line item descriptions, prices, and quantities, were mapped to Salesforce Opportunity Line Items. This ensured accurate and real-time updates to Salesforce opportunities.

- Mapping Customer Details: Shipping and billing addresses from EDI orders were mapped to Salesforce Account and Contact records, enabling quick and error-free creation or updates.

Key features of Magic xpi include:

- Pre-Built Connectors: Magic xpi offers pre-built connectors for Salesforce CRM, enabling seamless integration without extensive custom coding. These connectors ensure compatibility with Salesforce APIs and simplify the mapping of EDI fields to Salesforce objects such as Opportunities, Orders, or Accounts.

- Visual Data Mapping: Magic xpi’s intuitive visual interface allows developers to map EDI data fields (e.g., from X12 850 purchase orders) to corresponding Salesforce fields. For example, the “Item Number” in the EDI document can be mapped to the “Product Code” in Salesforce, ensuring accurate data transfer.

- Real-Time Data Processing: The platform supports real-time data flows, ensuring that incoming EDI documents are processed and pushed to Salesforce CRM almost instantaneously. This capability was critical for Opengear’s requirement to eliminate delays in order processing.

- Error Handling and Validation: Magic xpi includes built-in tools for data validation and error handling. For Opengear, this meant that any discrepancies in pricing or other critical fields were flagged during the mapping process, allowing for automated notifications and corrective actions.

- Scalability: As a cloud-based platform, Magic xpi is designed to handle increasing volumes of data and transactions. This ensured that Opengear’s integration solution could grow alongside their expanding business needs.

How Magic xpi Integrates EDI with Salesforce CRM

The integration process facilitated by Magic xpi involves several critical steps:

- Data Extraction: Magic xpi collects incoming EDI files from a designated mailbox. These files are then parsed and prepared for transformation.

- Transformation: The platform translates the raw EDI data into a format compatible with Salesforce CRM. This includes converting EDI segments like “BEG” (beginning segment for purchase orders) into Salesforce fields such as “Order ID.”

- Data Mapping: Using Magic xpi’s graphical interface, the transformed data is mapped to specific Salesforce fields. This step ensures that all critical information, such as customer details, order items, and pricing, is accurately captured.

- Validation: Before transferring data, Magic xpi validates it against predefined business rules. For instance, if an order contains an invalid product code or mismatched pricing, the platform triggers an alert.

- Data Transfer: Once validated, the data is pushed into Salesforce CRM via the pre-configured connector. Magic xpi ensures that the integration adheres to Salesforce’s API guidelines, maintaining data integrity and security.

- Notifications: Magic xpi sends automated email notifications to relevant stakeholders, summarizing the results of the data transfer and highlighting any issues that require attention.

Positive Experience During Integration

Throughout the integration process, Opengear experienced exceptional support and expertise from the EDI2XML team. The specialists at EDI2XML demonstrated a deep understanding of EDI processes and Salesforce integration, ensuring a smooth and efficient implementation. Their responsiveness to inquiries and proactive approach to problem-solving left a lasting impression on the Opengear team. Any questions or concerns were addressed promptly, and the team’s professionalism and technical competence exceeded expectations.

Opengear particularly appreciated the clear communication and collaborative mindset of EDI2XML’s specialists. Regular updates and progress reports kept the project on track, and their commitment to delivering a tailored solution underscored their dedication to client success. As a result, the integration process was not only seamless but also a valuable learning experience for Opengear.

Given the nature of the Fully Managed EDI Service, Opengear continues to rely on EDI2XML for ongoing support and maintenance. This partnership ensures that Opengear’s EDI processes remain optimized and scalable, providing confidence as their business grows.

Results and Benefits

Opengear experienced significant improvements in operational efficiency and business performance:

- Enhanced Efficiency: Automation eliminated manual data entry, reducing errors and freeing up employee time for strategic tasks. Staff could focus on value-added activities, improving overall productivity.

- Improved Accuracy: Real-time data validation ensured consistent and reliable order processing. The solution significantly reduced the incidence of errors, enhancing order accuracy and customer satisfaction.

- Scalability: The cloud-based solution scaled effortlessly with Opengear’s growing transaction volume, accommodating new trading partners and document types as needed.

- Faster Fulfillment: Automated workflows accelerated order processing and fulfillment times. Opengear could now process orders within minutes of receipt, improving responsiveness.

- Cost Savings: Reduced manual work minimized labor costs and errors, contributing to overall cost efficiency.

- Improved Relationships: Real-time updates and streamlined communication strengthened partnerships with trading partners, fostering trust and collaboration.

Client Testimonial

Dom Battista, Director of Global Sales Operations at Opengear, shared his thoughts on the EDI implementation:

“The integration was flawless—accurate, efficient, and incredibly quick. The EDI2XML team accommodated our needs at every step, ensuring a seamless transition. This solution transformed our operations, allowing us to scale and keep up with the demands of a growing business.”

EDI Integration FAQ

1. What is EDI integration with Salesforce CRM?

EDI integration with Salesforce CRM involves automating the process so that business documents like purchase orders (EDI 850) and invoices (EDI 810) are transformed into a format compatible with Salesforce and directly entered into Salesforce without manual data entry. This is specifically for trading partners who use Salesforce as their CRM. This eliminates manual data entry, ensuring accuracy and efficiency.

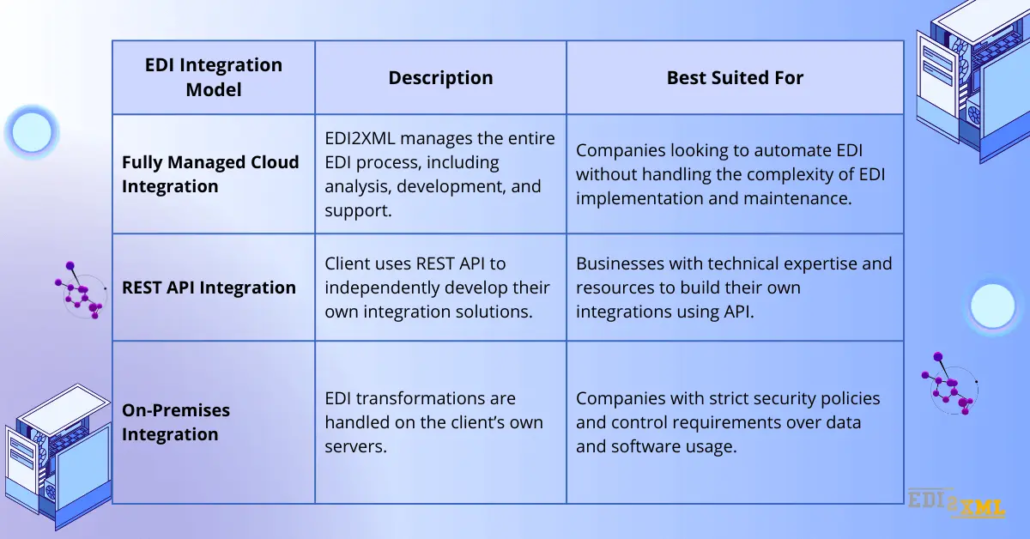

2. How does a Fully Managed EDI Service work?

A Fully Managed EDI Service from EDI2XML handles all aspects of EDI implementation, including document collection, transformation, and integration. It also includes continuous monitoring and support to ensure smooth operations.

3. What are the benefits of automated EDI processes for small businesses?

Automated EDI processes reduce manual effort, minimize errors, improve scalability, and enhance trading partner relationships. They enable small businesses to operate more efficiently and compete effectively in their markets. Moreover, small EDI-compliant companies can quickly begin doing business with large retailers like Costco, Walmart, and Target that require EDI for their transactions.

4. How long does it take to implement EDI integration?

Implementation timelines vary, but EDI2XML’s solution for Opengear was completed within one month, showcasing the potential for rapid deployment with minimal disruption.

5. What is the role of the Magic xpi connector in this solution?

The Magic xpi connector acts as a bridge between the EDI2XML platform and Salesforce CRM, ensuring seamless data transformation and transfer.

Glossary of Terms

AS2 (Applicability Statement 2): A communication protocol used for securely exchanging EDI documents over the internet. AS2 ensures reliable and encrypted transmission between trading partners.

X12 850 (Purchase Order): A standard EDI transaction set used by businesses to place purchase orders with their suppliers. It includes details like item descriptions, quantities, and prices.

Functional Acknowledgment (997): An EDI document sent to confirm the receipt of another EDI document, ensuring that it was successfully received and processed without errors.

EDI (Electronic Data Interchange): A standardized method for exchanging business documents (e.g., purchase orders, invoices) between companies electronically, eliminating the need for manual data entry.

Salesforce CRM: A cloud-based customer relationship management platform that allows businesses to manage sales, service, and customer interactions efficiently.

Magic xpi Integration Platform: A middleware solution that connects different systems, applications, and services, enabling seamless data integration and communication between them. It provides pre-built connectors and tools to facilitate integrations like Salesforce and EDI systems.

Integration: The process of connecting different systems, software, or platforms to work together as a unified solution. Integration ensures seamless data exchange and streamlines workflows across platforms.

Cloud-Based Solution: Software or services hosted on remote servers and accessed via the internet, offering scalability, flexibility, and reduced infrastructure costs.

Trading Partner: A business entity (e.g., supplier, distributor) involved in exchanging EDI documents with another organization.

Mapping: The process of linking data fields from one format (e.g., EDI) to another (e.g., Salesforce CRM) to ensure accurate data transfer and compatibility between systems.

Validation: A process to ensure that incoming or outgoing data meets predefined criteria or standards, such as correct pricing, formatting, or completeness.

Conclusion – EDI Integration

By partnering with EDI2XML, Opengear successfully modernized their business processes, overcoming inefficiencies and preparing for future growth. This case study demonstrates the power of a tailored, fully managed EDI solution in driving operational excellence and scalability for growing businesses.

The seamless integration with Salesforce CRM has positioned Opengear to meet increasing demands, maintain exceptional service standards, and achieve long-term success.

Want to streamline your EDI integration like Opengear? Contact EDI2XML today for a free consultation!