Many different processes take place in the warehouse every day, whether it’s a regular or 3PL warehouse. All of them must be carried out quickly and accurately. In this article, we will look at the importance of using EDI (Electronic Data Interchange) especially, an electronic document – EDI 945 Warehouse Shipping Advice associated with shipment of goods. Let’s figure out who and when to use EDI 945, what information a Warehouse Shipping Advice contains, 945 EDI specifications, benefits of using this EDI document, and much more.

What is EDI 945 transaction?

The Warehouse Shipping Advice Transaction Set (EDI 945) is an electronic data interchange (EDI) document. EDI 945 is usually used by 3PL warehouse/ remote warehouse or third-party logistics company, to notify its client (depositor) that a shipment has been made. It is used to match order quantities with shipment quantities.

945 EDI document type

EDI X12 945 Warehouse Shipping Advice Transaction Set is a document base on the X12 standard. X12 is a non-profit, ANSI-accredited standards development organization for cross-business transactions that support electronic data interchange in North America.

Each set of EDI transactions is supported by a subcommittee working within the X12 Accredited Standards Committee. EDI 945 falls under X12M – Supply Chain Subcommittee.

How is EDI 945 – Warehouse Shipping Advice used?

When a supplier/depositor (for example, a manufacturer or a wholesaler) needs to ship goods from the warehouse, he sends his 3PL warehouse an EDI document 940 Warehouse Shipping Order. EDI 940 contains all the necessary information regarding the goods required for shipment (description and quantity of goods, delivery date, recipient information, etc.) as well as shipping instructions.

Useful Reading: What is EDI 940 Warehouse Shipping Order?

The warehouse, having received the EDI 940, makes the shipment of the order and returns the EDI 945 immediately after the parcel has left the warehouse.

EDI 945 transfers detailed information about the merchandise shipped and the detail of the delivery.

Based on transaction EDI 945, the supplier can generate EDI 856 Advance Ship Notice as needed to notify its customer of an upcoming delivery.

What is the shipping process in a warehouse?

Shipment is the process of preparing and sending goods to the designated location. The shipping procedure at the warehouse is carried out according to predetermined rules. Each company develops shipping regulations independently, taking into account the characteristics and specifics of the goods and warehouse space.

The procedure for shipping goods from the warehouse/ 3PL warehouse can include many stages:

- processing of the depositor’s order (for example, entering data into the warehouse system);

- checking the availability of goods in the warehouse;

- receiving a picking list;

- selection of the necessary goods from the storage place;

- moving to the picking area;

- packaging and labeling in containers/pallets;

- loading of transport;

- Preparation and entry into the warehouse system of the relevant information.

The main task of the warehouse manager is to organize efficient work, which will ensure fast processing of orders since all shipments must be carried out on time.

Automation of warehouse processes, for example, the use of EDI can significantly improve the quality and speed of shipment of goods.

Workflow to Exchange Warehouse Shipping Advice (EDI 945)

Let’s take a closer look at the process of shipment of goods from a third-party warehouse and analyze what other EDI documents are involved in the logistics process. Of course, keep in mind that the process below may reflect only one of the possible options. Each company can establish its own business process with a third-party warehouse, which depends on the type of the company’s activity, type of product, etc.

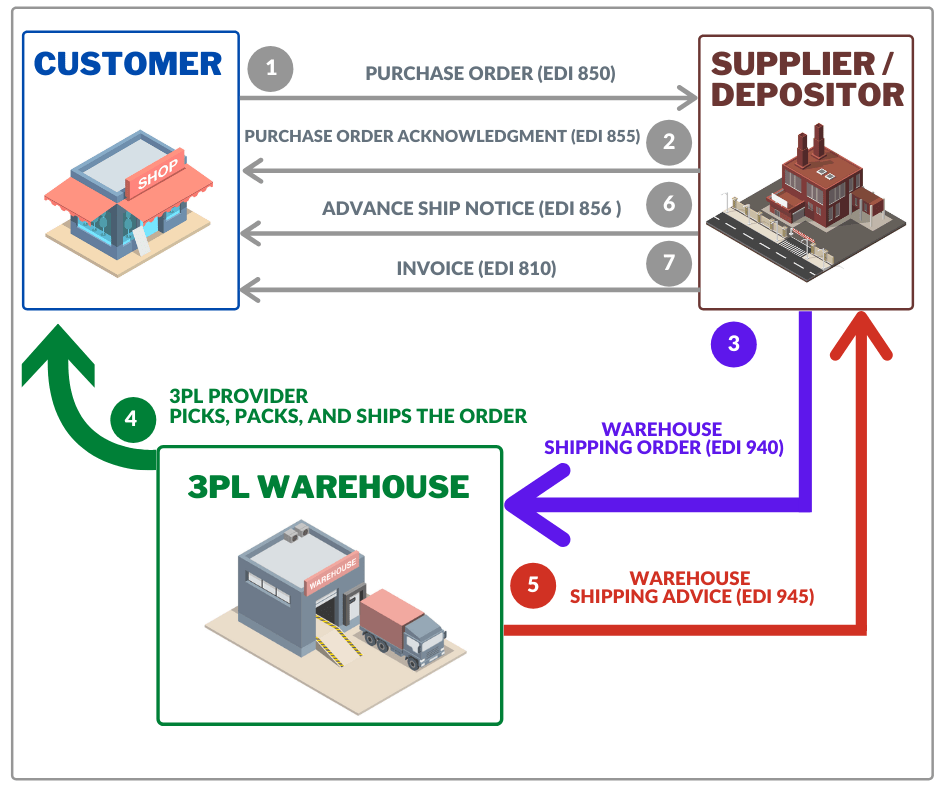

In the figure below you can see that usually the process in which EDI 945 is involved consists of at least three participants:

– Customer (it could be a retail outlet)

– Supplier (who is a client of the 3PL warehouse, or a depositor)

– 3PL Warehouse / or 3 PL logistics company.

1. The business flow begins with a Purchase Order – EDI 850 which is sent by the customer to the supplier.

2. The supplier responds to the customer with the EDI 855 PO Acknowledgement

3. The supplier sends the Warehouse Shipping Order (EDI 940) to the 3 PL warehouse

4. 3PL Warehouse process a Shipping Order and sends the goods to the supplier’s customer by the address specified in EDI 940.

5. Immediately after dispatch, the warehouse transfers the EDI 945 to the supplier.

6. Based on EDI 945, the supplier generates an Advance Ship Notice (EDI 856) and transfers it to his client.

7. The supplier sends the customer an EDI invoice 810

So, as you saw from the EDI workflow, 945 Warehouse Shipping Advice – is the main document, which confirms the fact of shipment of goods. It is used by many companies operating in wholesale and retail, including online stores.

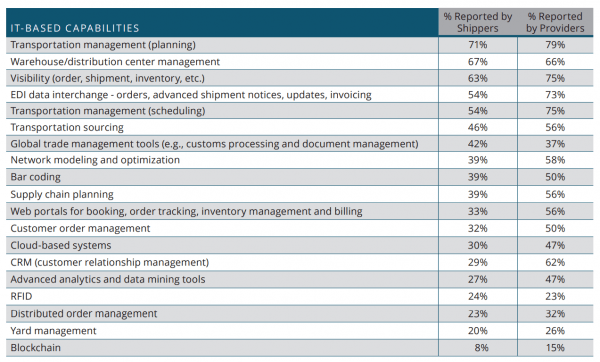

Useful Reading: EDI Integration for Transportation and Logistics

What information does EDI 945 contain?

EDI document Warehouse Shipping Advice contains accurate and detailed information about the item shipped from the warehouse. Thus, EDI 945 includes the following information:

- Information about the depositor, warehouse, and place of delivery (addresses, contacts).

- Details of the carrier and the method of delivery of the goods.

- Information about the product – cost, product name, SKUs, etc.

- The number of goods shipped.

- Complete order detail of the original order (EDI 940)

- Date and time of shipment from the warehouse.

- Transportation method

EDI 945 Warehouse Shipping Advice Structure

Like any other EDI document, EDI 945 transaction set has a precise structure and sequence of elements.

- ISA – Interchange Control Header

- GS – Functional Group Header

- ST – Transaction Set Header

- W06 – Warehouse Shipment Identification (numbers, dates, and other basic data)

- 0100 – Loop Name (to identify a party by type of organization, name, and code)

- N1 – Name

- N9 – Reference Identification

- G62 – Date/Time

- W27 – Carrier Detail

- W10 – Warehouse Additional Carrier Information

- 0300 – Loop Assigned Number

- LX – Assigned Number

- MAN – Marks and Numbers

- PAL – Pallet Information

- 0310 – Loop Warehouse Item Detail

- W12 – Warehouse Item Detail

- N9 – Reference Identification

- W03 – Total Shipment Information

- SE – Transaction Set Trailer

- GE – Functional Group Trailer

- IEA – Interchange Control Trailer

Benefits of using EDI 945 in Warehouses/ 3PL warehouses and Logistics

The use of EDI 945 in a 3 PL warehouses or 3 PL logistics company, allows you to get significant competitive advantages due to:

- increasing the speed and accuracy of logistics operations;

- reducing the cost of manual processing of documents;

- reducing the risks of losses and information inaccuracies;

- Increasing the speed of order processing due to receiving timely, fast, and accurate information.

Thus, automation of warehouse processes through the use of EDI document such as EDI 945, significantly improves the quality of 3PL warehouse processes.

Automate Warehouse Shipping Advice with EDI2XML Web Service

We have a ready-made EDI solution for the exchange of electronic documents in the X12 and EDIFACT standards. It is a unique HTTP service running over the internet that is capable of receiving HTTP requests to translate EDI messages to XML, and XML to EDI.

Try all the possibilities of the EDI2XML Web Service for free. We offer a 15 days free trial.

Contact us for a free consultation and find out how within an hour you can start exchanging electronic documents such as EDI 945 and many others with your trading partner.

You may also be interested in reading about:

– Electronic Data Interchange (EDI) in the Supply Chain

– How EDI can speed the receiving of goods in a warehouse

– EDI for Third-Party Logistics providers (3PL)

– DELFOR, DELJIT, DESADV – key EDI messages in supply chain management for manufacturing